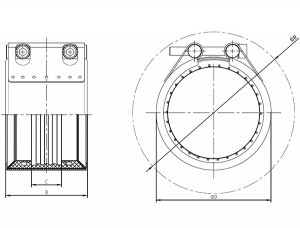

Xiuntata Axially Tare da Doublearƙirar Zobba Biyu

An tsara haɗin GRIP-G don maye gurbin buƙata ta walƙiya, walda, ragargaza bututu da zaren zaren ta hanyar samar da mafita cikin sauri da sauƙi don shiga bututu mai ƙarewa. GRIP-G yana da zobba biyu na anga waɗanda aka sanya kusa da su, amma an raba su daga, hanyar hatimin.

Ya dace da girman bututu daga OD φ26.9 zuwa-φ273mm.

Ya dace da kayan bututu: Karfan ƙarfe, ƙarfe mai ƙyalli, jan ƙarfe, cunifer, jifa da baƙin ƙarfe, GRP, galibin filastik da sauran abubuwa.

GRIP-G Axially an kame shi tare da zoben anga biyu haɗuwa shine mafi shaharar nau'in a cikin jerin haɗin GRIP. Zobbayen anga biyu suna da tasiri na anka, yana da sauƙi a kan bututu, yayin da matsa lamba ya ƙaru, haka ma tasirin kamewa. GRIP-G yana ba da babban matakan tsaro ta kulle bututu tare cikin matsi. GRIP-G matsin aiki har zuwa sandar 46. Yanayin zafin jiki: -30 ℃ har zuwa 180 ℃, abu a cikin SS304, SS316 da SS316TI. Ya dace da yawancin aikace-aikace a ginin jirgi, masana'antun teku, ruwa da maganin sharar gida, aikin bututu na masana'antu da sauransu.

GRIP-G Sigogin fasaha

Zaɓin Kayan GRIP-G

| Kayan abu / Aka gyara | V1 | V2 | V3 | V4 | V5 | V6 |

| Casing | AISI 304 | AISI 316L | AISI 316TI | AISI 316L | AISI 316TI | |

| Kusoshi | AISI 304 | AISI 316L | AISI 316L | AISI 304 | AISI 304 | |

| Sanduna | AISI 304 | AISI 316L | AISI 316L | AISI 304 | AISI 304 | |

| Anchoring zobe | AISI 301 | AISI 301 | AISI 301 | AISI 301 | AISI 301 | |

| Rigar da aka sanya (na zaɓi) | AISI 301 | AISI 301 | AISI 301 | AISI 301 | AISI 301 |

Kayan roba

| Kayan hatimi | Mai jarida | Yanayin zafin jiki |

| EPDM | Duk ingancin ruwa, ruwa mai lalacewa, iska, daskararru da kayayyakin sinadarai | -30 ℃ har zuwa + 120 ℃ |

| NBR | Ruwa, gas, mai, mai da sauran makamashin ruwa | -30 ℃ har zuwa + 120 ℃ |

| MVQ | Babban ruwa mai zafin jiki, oxygen, ozone, ruwa da sauransu | -70 ℃ har zuwa + 260 ℃ |

| FPM / FKM | Ozone, oxygen, acid, gas, mai da mai (kawai tare da tsiri saka) | 95 ℃ har zuwa + 300 ℃ |

Fa'idodin Hadin GRIP

1. Amfani da duniya

• Haɗu da kowane tsarin haɗin gargajiya

• Haɗa bututun kayan aiki iri ɗaya ko masu kama da juna

• Gyara da sauƙi mai sauƙi na bututun da aka lalata ba tare da katsewar sabis ba

2.Gaskiya

• Danniya-ba, m bututu hadin gwiwa

• Ya biya nauyin motsi da karkatarwa mai kusurwa

• Matsa lamba-juriya da zuba-hujja ko da tare da kuskure bututu taro

3.Easy handling

• M da reusable

• Kulawa kyauta kuma babu matsala

• Babu jituwa mai cin lokaci da dacewa

• Fasahar shigarwa mai sauƙi

4.Durara

• Sakamakon hatimi na ci gaba

• Ci gaba mai dorewa

• Lalata resistant da zazzabi resistant

• Kyakkyawan juriya ga sunadarai

• Lokaci mai tsawo

5.Shigar da sarari

• Karamin zane don sararin ceton sararin samaniya

• Nauyin nauyi

• Yana buƙatar ƙaramin fili

6. Azumi da aminci

• Sauki mai sauƙi, babu wuta ko haɗarin fashewa yayin sanyawa

• Babu farashi don matakan kariya

• Yana shafar vibration / oscillations